Sustainability Management in Governance & Economic Dimension

The Group is committed to conducting business ethically, in accordance with its Good Corporate Governance Policy, Code of Business Conduct, and risk management principles. This includes responsible investment in new businesses, compliance with all relevant domestic and international laws and regulations including tax obligations in all operating jurisdictions, and a firm stance against corruption and bribery. The Group promote transparency and traceability, encourage fair competition, and uphold social and environmental responsibility throughout the value chain. Furthermore, the Group aims to enhance long-term value creation by innovating technologies, processes, and business models that meet the evolving needs of customers and stakeholders. The Group also foster collaborative partnerships with suppliers and business partners to drive sustainable growth.

Good corporate governance has been a cornerstone of our operations since the Company's inception. The Group has established a comprehensive Corporate Governance Policy and Code of Business Conduct to guide its operations. The Corporate Governance Committee is responsible for ensuring effective, transparent, and accountable management of all Group activities. These policies are regularly reviewed and updated to maintain their relevance and alignment with international best practices.

Corporate governance refers to a structured system designed to foster transparency and responsibility among the Board of Directors and management team, thereby building trust with all stakeholders. Its primarly objective is to enhance long-term competitiveness, create value for shareholders, and generate sustainable value.

The Company’s corporate governance principles are as follows:

- Compliance with legal requirements: All management and business operations must adhere to applicable laws, charters, regulations, and resolution passed by the Board of Directors or relevant shareholders.

- Responsibility: All stakeholders, including the Board of Directors and management team, must be fully aware of and fulfill their duties and responsibilities.

- Transparency: Business operations and activities must be traceable and transparent.

- Participation: The Group acknowledges and respects the rights of shareholders and other stakeholders to participate in the Company’s activities.

- Value protection: Investments and resource utilization must be considered based on their potential for finance and economic returns.

-

Quality and Safety of Products and Services

-

Quality and Safety of Products and Services

The Group is committed to prioritizing the quality and safety of its products and services, recognizing these as key success factors for the business. Through continuous efforts in new products development and innovation, the Group aims to minimize environmental impacts across its value chain and contribute to sustainable production and consumption.

Quality and Safety of Products and Services (3-3)

The Group prioritizes the quality and safety of its products and services, recognizing them as critical factors in customer decision-making. The Group also acknowledges the importance of environmental management and operational stability. To this end, the Group strives to enhance the delivery of high-quality and safe products and services, fostering customer confidence and trust, maintaining the existing customer base, and expanding into new market segments. The Group actively seek feedback from all groups of relevant stakeholders, both internal and external, to continuously improve, adjust, and develop the products and services, ensuring sustainable business growth and long-term success.

The Group operates in alignment with action plans, setting performance targets tailored to the specific nature of business unit. Post-implementation assessments are conducted to evaluate the effectiveness of these action plans, ensuring continuous improvement in product and service quality and safety.

Communication via Product

The Company has implemented a policy requiring subsidiaries engaged in consumer goods production to enhance communication methods and product information. This aims to provide accurate, up-to-date, and comprehensive consumer knowledge about the products. Various communication channels are utilized, including product labeling, printed materials, online media, and direct customer hotlines, ensuring consumers receive precise and timely information.

Thoresen Shipping: TSS

Quality and Safety of Products and Services Management Approach

The company prioritizes product safety and on-time service delivery, emphasizing excellent customer service with speed and efficiency. To ensure the highest level of customer satisfaction, TSS maintains consistent communication and coordination with customers through a team of dedicated professionals, enabling customers to easily contact the company and track their shipment status in real-time.

Thoresen Shipping adheres to service provision requirements and conditions according to the Charter Party contract and complies with international and local marine standards for shipping. This ensures the ability to provide efficient global shipping services while minimizing risks related to non-compliance with applicable laws, regulations, and requirements. Thoresen Shipping has 2 key departments responsible for maintaining service quality. The Commercial Operations team handles transportation management in accordance with established standards and contractual agreements, while the Marine Operations team oversees crew resource management and ensures that vessels are fully prepared to deliver high-quality and safe services.

TSS also welcomes feedback and suggestions from customers to continuously enhance and improve service quality. For more details, please visit www.thoresenshipping.com

Quality and Safety of Products and Services Activities and Initiatives

TSS recognizes the importance of providing excellent services that meet customer needs for maximum satisfaction. The company regularly organizes training sessions and workshops on cargo management for crews to ensure that they possess the necessary knowledge and expertise to handle products safely, while delivering the highest quality of service to customers.

PH Capital: PHC

Quality and Safety of Products and Services Management Approach

PHC prioritizes product quality and safety, recognizing their direct impact on customers' quality of life and hygiene. Potential risks in these areas could damage the company's credibility and require significant time and cost to rectify. Therefore, the company is committed to strictly adhering to food safety regulations to minimize risks to customers and mitigate problem resolution costs. This commitment enhances the reliability of the company's products and services, fostering customer satisfaction, trust, and repeat purchases.

PHC is committed to maintaining strict and consistent standards of cleanliness and safety as fundamental to its business operations. The company has a food safety control policy that fully complies with regulations and food safety laws set by the Food and Drug Administration (FDA). Furthermore, the company adheres to the food quality and safety policies as per the Franchise Policy and company requirements of Yum! Brands Inc. which includes internal and external expert inspection and risk evaluation processes to reduce risk factors. Additionally, collaborative discussions with raw material, packaging, and storage suppliers are conducted to determine preventive measures, and continuous monitoring of operations is carried out to consistently mitigate quality and safety risks. The details of the company's food quality and safety management are as follows:

Restaurants

- All restaurants are regularly audited by internal audit and external audit from the National Sanitation Foundation (NSF), which is certified by Yum! Brands Inc.

Suppliers

- Suppliers, including food products and packaging distributors, storage, and distribution providers, are audited according to Food Safety Policy and Yum! Brands Inc. standard at least once a year or other relevant standards such as BRC or FSSC22000.

- Purchasing vegetable products from producers who comply with Good Agricultural Practice (GAP) standards and have food safety control policies in place.

- Suppliers delivering raw materials to PHC must have Global Food Safety Initiative (GFSI) Certificate before commencing product transactions to ensure product safety. This will be implemented starting from 2025.

- For new product ingredients, the company will begin by selecting suppliers with GFSI certification before product development to ensure that PHC obtains quality products that are safe for consumers.

- For products with usage exceeding Baht 5 million per year, the company will conduct annual random quality, taste, chemical, and microbiological safety inspections.

- Suppliers, including food products and packaging distributors, storage, and distribution providers, are audited according to Food Safety Policy and Yum! Brands Inc. standard at least once a year or other relevant standards such as BRC or FSSC22000.

- Purchasing vegetable products from producers who comply with Good Agricultural Practice (GAP) standards and have food safety control policies in place.

- Suppliers delivering raw materials to PHC must have Global Food Safety Initiative (GFSI) Certificate before commencing product transactions to ensure product safety. This will be implemented starting from 2025.

- For new product ingredients, the company will begin by selecting suppliers with GFSI certification before product development to ensure that PHC obtains quality products that are safe for consumers.

- For products with usage exceeding Baht 5 million per year, the company will conduct annual random quality, taste, chemical, and microbiological safety inspections.

- Branch managers must possess a food handler certificate issued by the Ministry of Public Health.

- The company has a policy to provide food safety training to all restaurant employees, both in classroom and online formats, and a policy requiring branch employees to undergo health check-ups before starting employment. Additionally, there are strict measures in place to ensure employees wash their hands every time the employees enter the food preparation area and before handling food, to ensure that products prepared within the restaurant are safe before being delivered to customers.

Customers

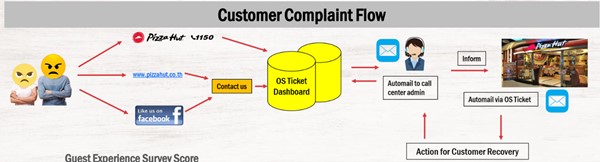

- The company has channels for receiving complaints regarding product and service quality and safety through call center 1150, Facebook, and e-mail, along with defined operational procedures for investigating complaints and implementing preventive measures to avoid recurrence.

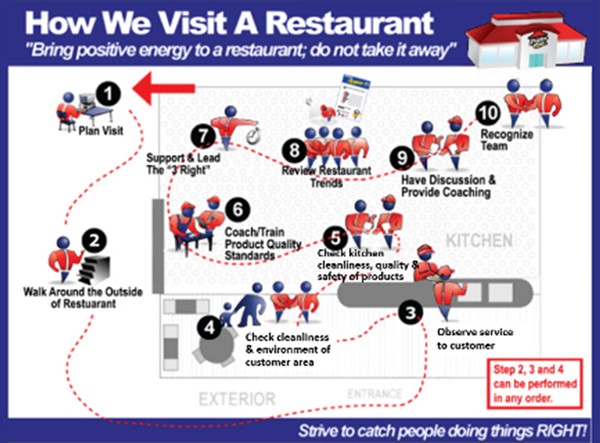

Restaurant Inspection Process

PHC is committed to delivering quality and safe food, prioritizing the good hygiene of consumers. Therefore, the company aims to conduct annual food safety inspections of restaurants, including all suppliers. The company's branches must pass inspections according to standard requirements, which include food safety standards, brand standards, and domestic legal standards, with an average of 2.35 inspections per year. These inspections are conducted by certified and experienced external parties in food quality and safety, assigned by the franchisor, to analyze the problems of each restaurant and implement improvements.

Each Pizza Hut branch has its manager responsible for food quality and safety, as well as conducting quality control inspections. Additionally, PHC has a Food Safety Committee, consisting of 2 Supply QAs and 2 Restaurant QAs. This committee holds meetings to discuss inspection results and uses these results to identify ways to improve and develop service, and presents them to team leaders, the store management team, and relevant departments to manage operational processes and ensure food quality and safety before it reaches consumers. Furthermore, consumers can access nutritional and dietary information (Nutrition Transparency) on the company's website.

In addition, PHC has channels for receiving complaints regarding product and service quality and safety through various means, including Call Center 1150, the company's website at www.pizzahut.co.th, and social media at www.facebook.com/pizzahutthailand. If consumers have complaints regarding product and service quality and safety, the call center will conduct an initial investigation and report to the operations department for further investigation. After reviewing the investigation results, they will proceed with corrective actions and provide compensation to the customer through the operations department. Subsequently, the company will summarize the complaint issues to identify preventive measures to avoid recurrence.

Quality and Safety of Products and Services Activities and Initiatives

Training for operators and food handlers

The company received approval from the Department of Health to be a training management organization in 2021, enabling the company to fully train employees. This allows employees to apply their knowledge correctly and provide services that prioritize consumer health and safety.

In 2024, the company continued to provide ongoing training to employees who are responsible for sourcing raw materials, preparing and cooking food, and providing food services, with a focus on food safety. This year, a total of 1,568 employees received training to ensure that employees perform their duties in accordance with the company’s standards and prioritize food quality and safety.

In addition, the company also provides training to external food business operators and food handlers through Pizza Hut's Technical Training and Development department.

Food Quality and Safety Training

In 2024, the Human Resources department conducted training and development for employees involved in food quality and safety.

Performance

In 2024, all Pizza Hut restaurant staff received comprehensive training in food quality and safety to ensure service standards and safe food handling. For raw materials, the company purchases vegetable products from producers certified under Good Agricultural Practice (GAP) standards, to guaranteeing ingredient quality and safety. For other raw materials, the company sources products from GFSI-certified suppliers, adhering to international standard, and maintains a robust food safety control policy. These measures build customer confidence throughout the production and service process.

Quality and Safety of Food and Services Training Performance

Participant in Quality and Safety of Food Training Percentage of Participant Trained in Quality

and Safety of Food2022 2023 2024 Employee 100 100 100 Supplier 100 100 100 Performance Percentage of employee passing quality and safety of food trainings (percentage) 100 Incidents of non-compliance concerning health and safety impacts of products and services (case) (416-2) 0 PM Thoresen Asia Holdings: PMTA

Quality and Safety of Food and Services Management Approach

To protect people’s health condition and environment in the country, Baconco has complied with Vietnamese government policy by stopping using Glyphosate, an herbicide which may cause cancer. There is other 54 types of herbicides which are also effective, safe and can be substituted for Glyphosate. Recognizing the safety of its products to its consumers, Bacanco sells the herbicide with characteristics that can substitute Glyphosate to its customers, which also brings consistently increased revenue.

Siam Taco: STC

Quality and Safety of Food and Services Management Approach

To be number one in the hearts of customers and to be a Mexican-style fast-food restaurant that provides fast, accurate, and friendly service, STC has created a project to set service time targets, aiming to provide service within 4 minutes per 1 customer, with operational methods to achieve this goal by promoting expertise in each position at every step of customer service, encouraging training and excellent problem-solving skills. As a result, in 2024, STC was able to provide service in 3.6 minutes per 1 customer.

Unique Mining Services (UMS)

Quality and Safety of Food and Services Management Approach

UMS has a key product strategy that involves selecting and improving the quality and efficiency of coal through a process of quality control and quality assessment by a team of experts and professionals to assess coal quality in terms of carbon content, moisture level, and concentration of sulfur dioxide. Each customer will receive coal quality that is suitable for the steam boilers of their respective industrial plants for maximum efficiency in fuel combustion.

-

Customer Relationship and Complaint Management

-

Customer Relationshipand Complaint Management

The Group recognizes the importance of customer relationship management for retaining customers, acquiring new ones and prioritizing systematic complaint management to improve and develop the operations, ensuring to effectively meet customer needs.

Customer Relationship and Complaint Management(3-3)

The Group is committed to meeting customer needs to enhance satisfaction and positive customer experiences. Recognizing that customer satisfaction and strong relationships are fundamental to long-term business sustainability, the Group aims to develop high-quality, standardized products and services across all business units to meet customer expectations. Appropriate, accurate, and responsible marketing practices are in place so customers receive reliable information for decision-making. Furthermore, the Group provides various channels for customers to provide feedback, suggestions, and satisfaction evaluations to continuously improve the quality of the operations, products, and services, ensuring that customers receive products and services that meet their needs to the greatest extent possible. This approach helps retain the existing customer base and encourages its expansion, driving the Group's continued growth.

Code of Business Conduct: Guidelines for Dealing with Customers

To comprehensively and precisely meet customer needs, the Group has incorporated guidelines for interacting with customers as part of its Code of Business Conduct. This is communicated to all employees and relevant parties, and regular knowledge assessments are conducted. The Group's Code of Business Conduct was initially implemented in December 2009 and was last reviewed and revised in 2024. The guidelines for customer interaction within the Code of Business Conduct include:

- Delivering quality products and services that meet customer expectations.

- Providing accurate, complete, and timely information about the company's products and services to customers.

- Strictly complying with the terms and conditions provided to customers.

- Treating customers politely and efficiently to gain their trust.

- Maintaining customer confidentiality and avoiding the use of such confidential information for personal gain or for the benefit of others.

Thoresen Shipping: TSS

Customer Relationship and Complaint Management Approach

Thoresen Shipping is an international dry-bulk shipping service provider, operating to globally recognized international standards. The company provides sea freight services to all regions of the world, tailored to customer needs, transporting a variety of goods, including iron ore, coal, agricultural products, construction materials, and steel, etc.

In terms of customer relations, the company recognizes that providing excellent service, characterized by standards, reliability, and timely responses, is a key driver for business success and sustainable growth.

The entire fleet is managed by a team of experienced professionals based in offices in Singapore, Thailand, England, and the United Arab Emirates. The company prioritizes maintaining standards, operational efficiency, and personnel skills to ensure prompt and efficient responses to customer freight transport needs.

In 2024, the company received no complaints and incurred no fines or penalties related to breaches of customer confidentiality.

Moreover, in 2024, the company continued to earn customer trust, evidenced by a high rate of repeat business. Over 80 percent of the top 10 customers from 2023 returned to utilize the company's sea freight services in 2024.

Performance in 2024

Incidents and complaints from customers Case Incidents or complaints related to the violation of customer confidentiality 0 PH Capital: PHC

Target in 2024

Target Performance Customer Satisfaction (Win score method) at 64 percent 81 percent Customer Relationship and Complaint Management Approach

PHC focuses on creating a positive customer experience through food safety and service quality. The company is committed to enhancing this experience by actively listening to customer feedback and suggestions regarding food and service. This helps us to understand evolving customer needs and behaviors, build satisfaction and loyalty, and expand the customer base. Additionally, the company adheres to consumer protection guidelines through responsible advertising, ensuring fairness and avoiding exaggerated or misleading statements about the products and services.

PHC focuses on creating a positive customer experience through food safety and service quality. The company is committed to enhancing this experience by actively listening to customer feedback and suggestions regarding food and service. This helps us to understand evolving customer needs and behaviors, build satisfaction and loyalty, and expand the customer base. Additionally, the company adheres to consumer protection guidelines through responsible advertising, ensuring fairness and avoiding exaggerated or misleading statements about the products and services.

Customer Relations Management Platform

PHC utilizes a system that facilitates database storage and customer relationship management, employing analytical tools and customer segmentation to systematically collect data and manage communication channels. The information obtained is used for various purposes, such as sales promotions and new product offerings, to effectively meet customer needs. This system also supports the creation of positive experiences and increases customer repeat purchase rates. PHC establishes goals and measures operational results for each project, using evaluation methods tailored to the specific objectives.

Guest Experience Survey

PHC has developed the Guest Experience Survey (GES) to improve its products and services. The survey covers aspects of satisfaction related to taste, quantity, price, ease of access to information or ordering channels, and service quality. The survey is conducted through questionnaires, online channels, and SMS messages. PHC then analyzes the survey results to identify problem areas and create monthly improvement plans. Furthermore, the company sets an annual target for the survey to measure customer satisfaction effectiveness and systematically evaluate customer relationship management performance

In 2024, PHC enhanced its customer satisfaction measurement by implementing the WIN Score Method, setting a performance target of 64 percent. The WIN Score Method combines scores from 3 components:

- Guest Experience Survey (GES)

- Food Aggregator rating which is an assessment through intermediaries between the company and consumers. PHC utilizes data from various applications, especially delivery applications, for this assessment.

- Social rating

Based on the past year’s Win Score Method assessment results, the company achieved 81 percent, exceeding the set target. To further enhance product and service efficiency and satisfaction, PHC has set annual operational challenging targets, including:

Year 2025 2026 2027 2028 2029 Target (percentage) 82 85 88 90 90 Action Plan for Improving Customer Satisfaction

In 2024, PHC’s goal is to prioritize speed of service in order to provide products to customers quickly and still hot within 30 minutes. As a result, PHC can deliver products to customers within an average of 32.4 minutes.

Complaint Management Flow

PHC provides channels for customers to submit complaints, suggestions, and feedback on the company's products and services, using the information to improve and develop operations. If a complaint relates to restaurant service, the restaurant manager will analyze the issue, identifying the cause, location, and frequency of the problem, and summarize the compliant to develop preventive measures to avoid recurrence and evaluate resolution results. In 2024, no health and safety compliants were received from Pizza Hut restaurants customers.

Channels of Receiving Complaints

- Call Center : 1150

- Website : www.pizzahut.co.th

- Mobile Application : Pizza Hut Thailand

- Restaurant

- Facebook: Pizza Hut

Customer Relationship and Complaint Management Activities and Initiatives

Enhancing Communication and Complaint Management Efficiency

In March 2024, PHC enhanced internal communication efficiency for receiving customer complaints, feedback, and suggestions from Home Services (Call Center 1150). Improved customer complaint tracking now enables store fronts to quickly check on and address complaints more systematically and directly.

Additionally, the company introduced a LINE Official channel for customers to report incidents, with area and store managers coordinating to resolve complaints within 2 hours.

Performance in 2024

Customer Satisfaction Percentage Overall customer satisfaction score (Win Score Method) 81 Customer Complaints Management Case Total number of customer complaint cases 803 Number of incidents or complaint cases related to consumer rights violations 0 Number of incidents or complaint cases related to product and service quality and safety 151 Number of incidents or complaint cases related to services 599 Number of incidents or complaint cases related to human rights violations 0 Number of other incidents or complaint cases 53 Number of complaints resolved 803 Siam Taco: STC

Customer Relationship and Complaint Management Approach

STC aims to become a Mexican food brand that first comes to customer's mind. To provide superior products and services, the company implements a strategy to maintain sustainable long-term customer relationships, which is a primary driver of business success and growth. The company conducts customer satisfaction assessments by encouraging customers to fill out an assessment form at the bottom of the receipt and submit their feedback. The survey contains questions in various dimensions such as satisfaction with products and services, cleanliness, and safety measures during the COVID-19 situation, et cetera. In addition, the company also sets satisfaction goals and conducts post-performance assessment to determine progress. The company focused on the improvement of operational standards in terms of speed of service to deliver the products and services to customers on time to optimize table turnover time and decrease congestion during rush hours.

Complaint channels

- Website : www.tacobell.co.th

- Facebook : Taco Bell Thailand

Performance in 2024

In 2024, there were no report of significant customer complaints from every channels. However, the company devised a contingency plan in case of complaints. If a complaint is reported, the customer service team will contact the customer for more details regarding the complaints or suggestions received, and apologize for the incident before offering solutions, in case of complaints beyond responsibility, the incident will be escalated to higher-level management for resolution. All complaints will be resolved within 72 hours and recorded in the system to prevent recurrence.

Unique Mining Services: UMS

Customer Relationship and Complaint Management Approach

UMS procures and verifies the quality of products that meet customer expectations, as well as continuously developing and improving production processes. The company has a dedicated department that provides consultation and customer service support for pre- and post-sales to promptly address customer issues by analyzing the causes of problems and providing solutions. Additionally, the company regularly visits and conduct meetings with customers to garner their feedback and suggestions and maintain a good relationship between the company and customers.

The company conducts business in conjunction with continuous product and service development to ensure customer satisfaction with responsibility, honesty, integrity, and business ethics. This is achieved by sourcing quality and standardized products and maintaining customer confidentiality. The company's managing director will regularly provide a report on customer relations to the Executive Committee and the Board of Directors.

Asia Infrastructure Management (Thailand): AIM

Customer Relationship and Complaint Management Approach

AIM has managed customer relationships in accordance with the strategy of developing a marketing business that focuses on responding to customer needs and being customer-centric. The company is in the process of studying customer relationship management to create a comprehensive operational guideline to respond sustainably to customer needs.

-

Value Chain Management

-

Value ChainManagement

Efficient and sustainable value chain management is crucial for ensuring the quality of an organization's products and services. Effective supplier management builds strong business partnerships, enabling the Group to meet customer demands effectively.

Value Chain Management (3-3)

Effective value chain management is a key driver of efficient business operations. The Group believes that a sustainable value chain management strategy strengthens business stability by fostering strong supplier relationships. This enhances credibility and mitigates risks within the value chain, including social, environmental, governance, and economic risks. Additionally, it ensures the procurement of high-quality raw materials, upholding the standards of the Group’s products and services and effectively meeting stakeholder expectations. This enables the Group to deliver superior customer experiences, fostering customer interest and demand while driving sustainable growth with a commitment to Environment, Social, and Governance and Economic (ESG) principles throughout the value chain.

The Group is committed to responsible business operations that prioritize accountability to communities, society and the environment across the entire value chain. It emphasizes ethical business conduct, compliance with laws and regulations and the prevention of negative impacts on all groups of stakeholders. Moreover, the Group is dedicated to raising supplier awareness regarding responsible business practices. The Group promotes collaboration with suppliers to jointly contribute to community, social and environmental development. This commitment is reinforced through the Supplier Code of Conduct, which is regularly updated to align with evolving circumstances.

Supplier Code of Conduct

The Company has established guidelines for supplier management by implementing Supplier Code of Conduct, which outlines the principles and best practices for fair procurement. This includes procurement regulations that the Group adheres to when conducting business with suppliers in a sustainable manner, as well as supplier selection criteria aligned with the Company’s strategic direction.

TTA’s Supplier Code of Conduct considers environmental and social factors alongside governance and economic aspects. TTA requires suppliers to acknowledge and sign the Supplier Code of Conduct and conduct an annual self-assessment to ensure compliance with its principles. Additionally, TTA may conduct inspections of suppliers' production processes and service delivery as deemed appropriate. Internal audits are also conducted for subsidiaries to ensure that suppliers adhere to the established criteria and regulations set by the Group.

Access more details on Supplier Code of Conduct: https://www.thoresen.com/storage/download/corporate-documents/20220520-tta-supplier-coc-en.pdf

Supplier Code of Conduct Guidelines

- Procurement with consideration for cost efficiency and effectiveness in terms of quality, price and service for the best benefit of the Company.

- Procurement with a focus on business ethics, ensuring fair treatment of suppliers, providing accurate, complete, and transparent information, and treat suppliers equally, including considering opinions and suggestions.

- Procurement that is transparent, fair, and traceable and adheres rigorously to relevant regulations and laws, while implementing risk management and good internal controls.

- Sustainable procurement and supplier management by considering Environment impact, Social responsibility and Governance and Economic factors (ESG), as well as monitoring suppliers to ensure compliance with the Supplier Code of Conduct as part of a sustainable value chain management approach.

Green Procurement Management Process

- Procurement officers must use resources efficiently to achieve maximum benefits and environmental friendliness.

- Consider products and services with no environmental impact.

- Support the use of products made from recyclable resources and do not cause environmental pollution, such as products with ecolabels certified.

- Consider suppliers and service providers with environmental standards certifications.

- Establish fair and equitable procurement procedures and methods.

Selection of the Company’s Suppliers

When it is necessary to procure goods and services, procurement officers will select suppliers from the Approved Supplier List according to the procedures and guidelines described below:

- Provide accurate, clear, and fair procurement requirements to all qualified suppliers to ensure equal opportunities for suppliers to offer the goods and services.

- The initial selection of new suppliers is based on key criteria, prioritizing the quality of goods and/or services, reasonable pricing, and other necessary requirements. New suppliers must complete a self-assessment covering product and service quality, business operations, social responsibility, and environmental responsibility to support the next stage of procurement approval.

- The procurement officers evaluate the supplier's self-assessment alongside product and/or service quality, pricing, and other necessary requirements.

- A score above 70 percent is considered a pass and the results will be presented to the approving authority.

- A score below 70 percent is considered as underqualified and requires further review. The procurement officers will notify the supplier and collaborate on preventive measures to address potential sustainability concerns with a follow-up evaluation in the next round.

- Approved suppliers are categorized as Critical Tier 1 Supplier or Critical Non-Tier 1 Supplier based on the criteria for supplier segmentation.

- After joining the Approved Supplier List, the existing suppliers must undergo a Yearly Performance Evaluation using the Company's supplier assessment along with the supplier’s self-assessment covering product and service quality, business operations, social responsibility, and environmental responsibility to monitor the performance. Throughout the year, the Company may raise concerns or report issues related to product performance, or Environment, Social, Governance and Economic aspects. The Company will investigate, determine corrective actions, provide recommendations, and develop the supplier’s capabilities together with related parties from all departments and suppliers before reassessing the situation.

Criteria for Supplier Segmentation

The Group establishes supplier segmentation criteria to enable systematic procurement analysis and strategy development, as well as effective supplier risk assessment. Suppliers are categorized based on the following criteria:

1. Critical Tier 1 Supplier

Suppliers with high contract value, high expenditure, limited alternative products and essential components or equipment critical to the production process, posing a significant risk to the Company's operational capability. This supplier group is required to undergo the Yearly Performance Evaluation through the Company's supplier assessment, combined with the supplier’s self-assessment and/or an onsite audit. The evaluation process covers product and service quality, business operations, social responsibility, and environmental responsibility.

2. Critical Non-Tier 1 Supplier

Suppliers with moderate service usage or lower contract value, posing a medium or low risk to the Company’s operational capability. These suppliers undergo the Yearly Performance Evaluation through the Company's supplier assessment, combined with the supplier’s self-assessment and assessments from relevant department(s). The evaluation process covers product and service quality, business operations, social responsibility, and environmental responsibility.

Supplier Risk Assessment

The key factor in enhancing value chain management efficiency is the risk assessment. The Group has implemented a supplier risk management system, which includes value chain risk assessment, company-conducted supplier assessment, and supplier’s self-assessment. These processes help identify key suppliers within the value chain and to check the qualifications of those who will be registered as suppliers of the Company. The key risk areas are as follows:

- Economic risks issues such as raw material price fluctuation risks, etc.

- Environmental risks such as greenhouse gas emissions, noise pollution, water usage and wastewater discharge, energy consumption and waste, raw materials, or equipment containing hazardous substances management, etc.

- Governance risks such as corruption, tax evasion, fair competition, and intellectual property, etc.

- Social risks such as human resources management, human rights, occupational health and safety and legal compliance, etc.

Average Supplier Payment Period in 2024

- Supplier Credit-Term according to internal practice is within 30 days.

- The actual supplier average credit-term in 2024 was 30 days.

Thoresen Thai Agencies: TTA

Value Chain Management Approach

With the Company’s commitment to establishing a foundation of sustainability across the value chain, the Supplier Code of Conduct has been developed. This serves as a guideline for the Company’s and the Company’s suppliers to follow, mitigating risks related to the environment and society. Additionally, supplier assessment guidelines have been established. Business partners of the Company are also required to sign an acknowledgment of the Supplier Code of Conduct to ensure strict adherence. Furthermore, the Company actively manages supplier relationships to foster continuous and sustainable business operations.

Value Chain Management Activities and Initiatives

Sort Before Dispose Project

In 2024, the Company contributed to the sustainable business development of its suppliers by organizing training under the " Sort Before Dispose" project for State Service Co., Ltd., a cleaning service provider responsible for maintaining the Company's headquarters. This initiative aimed to promote waste segregation in alignment with the Company's commitment to environmental responsibility across all areas. It also raised awareness among cleaning staff, ensuring they understood waste types and adopted proper waste segregation practices similar to the Company's employees. This training serves as a foundation for creating a sustainable environment together in the future. The knowledge gained will enable cleaning staff to correctly separate waste at the source and apply these practices at other locations where they work.

For the results, all 3 cleaning staff, representing 100 percent of the cleaning workforce, participated in the training. Pre- and post-training assessments showed a 100 percent pass rate. In 2024, correct waste segregation increased, leading to a 3.2 percent reduction in landfill waste and a rise in waste being repurposed. This included an increase in electronic waste and plastic bottles being sent for recycling.

Additionally, in 2024, the Company communicated the Supplier Code of Conduct alongside TTA’s Environmental Policy to 6 suppliers via e-mail, representing 7.2 percent of all suppliers. Furthermore, the "Separate Before Dispose" project included training sessions that also covered the Environmental Policy.

Performance in 2024

Total Number of Suppliers 83 persons Supplier Categories Number of Suppliers Percentage New Suppliers 6 7.2 Critical Tier 1 Suppliers 35 42.17 Critical Non-Tier 1 Suppliers 48 57.83 Supplier Code of Conduct Acknowledgement Number of Suppliers Percentage Suppliers that signed the Supplier Code of Conduct 6 7.2 Environmental Assessment of Suppliers Number of Suppliers Percentage New suppliers screened based on environmental criteria 6 7.2 Suppliers assessed for environmental impact 6 7.2 Suppliers with significant negative environmental impact 0 0 Suppliers with significant negative environmental impact that implemented improvements agreed upon with the Company 0 0 Suppliers with significant negative environmental impact that had contracts terminated due to the Company's assessment 0 0 Social Assessment of Suppliers Number of Suppliers Percentage New suppliers screened based on social criteria 6 7.2 Suppliers assessed for social impact 6 7.2 Suppliers with significant negative social impact 0 0 Suppliers with significant negative social impact that implemented improvements agreed upon with the Company 0 0 Suppliers with significant negative social impact that had contracts terminated due to the Company's assessment 0 0 ESG (Environmental, Social, Governance & Economic) Risk Management Number of Suppliers Percentage Suppliers assessed for sustainability risk 6 7.2 Suppliers identified as high risk 0 0 Suppliers that underwent On-site ESG audits 0 0 Suppliers with risk management measures implemented to mitigate impact 0 0 Payment Period for Suppliers Day Supplier Credit-Term according to Supplier Code of Conduct 30 Actual supplier average credit-term in 2024 30 Supplier Compliance Violations Case Number of violations 0 Thoresen Shipping: TSS

Value Chain Management Approach

Thoresen Shipping believes that one of the key factors driving competitive advantage and improving operational efficiency is the effective and sustainable management of the value chain. The company focuses on promoting sustainability and responsible practices throughout the supply chain. The company has set standards and operational guidelines for working with business partners, adhering to principles of integrity, fairness, and transparency.

TSS has established a procurement policy that focuses on products or services that meet high standards, are delivered quickly, and align with the company’s criteria and goals. In selecting and contracting with suppliers, the company follows international maritime standards to ensure the delivery of high-quality services on time. This process involves necessary evaluations and checks by the relevant departments to ensure that the products or services the company receives are of standard quality, provide maximum benefit, and outlines the approach to dealing with suppliers who fail to meet agreed terms.

Regarding payment terms, the company typically sets a 30-day payment period after the delivery of goods or services. This period may be adjusted based on specific criteria and agreements with each supplier.

Thoresen Shipping’s Supplier Management Guidelines

- Conduct operations in compliance with the Supplier Code of Conduct, relevant business laws and regulations.

- Ensure fair treatment of suppliers regarding terms, conditions, and payments.

- Operate with respect for human rights, fairness, and equality.

Value Chain Management Activities and Initiatives

The company conducted a supplier survey to understand suppliers’ policies, approaches, and targets related to sustainability management, covering environmental, social, health, and safety aspects. Among 30 surveyed suppliers, 28 suppliers, representing 93 percent of those surveyed, have established policies and targets for sustainability management within the organizations.

PH Capital: PHC

Value Chain Management Approach

PHC recognizes that the food business involves numerous suppliers. To meet customer demands in terms of quality and price while mitigating risks related to cost fluctuations, raw material shortages, and Environment, Social, Governance and Economic (ESG) risks within the supply chain, the company prioritizes strong supplier relationships. This approach ensures the consistent delivery of high-quality raw materials. Operating under a franchise agreement with Yum! Brands, Inc., PHC remains committed to responsible and efficient risk management throughout its supply chain. The company has established supplier policies and requirements aligned with international standards, as outlined below.

- Quality System Audit: An audit of a supplier’s production efficiency and quality control system.

- Distribution Audit: The inspection of warehouse quality, storage standards, contamination prevention measures, and transportation quality. This includes compliance with product-specific storage requirements, transport conditions such as temperature control, vehicle cleanliness, hygiene of delivery personnel, and loading/unloading procedures.

- Global Food Safety Initiative (GFSI) Certification: An international standard with the purpose of establishing standards on food safety and hygiene. If a supplier has implemented and been assessed under a GFSI-compliant quality system that meets PHC’s requirements, they may submit relevant documentation to be exempted from PHC’s standard audit.

Since product quality and food safety begin with high-quality raw materials, standardized production processes, proper storage of finished products, and systematic distribution, PHC has established procurement guidelines that prioritize integrity and transparency. These guidelines align with the company’s requirements and ensure that new suppliers are selected based on their social and environmental responsibility.

Each year, PHC categorizes key suppliers based on their strategic significance (Critical Component Suppliers), which directly impacts business competitiveness. All key and new suppliers undergo factory audits and risk assessments conducted by external auditors. PHC also conducts annual site visits to key suppliers to review production processes. Measures are in place to address non-compliance, and annual training sessions are held with suppliers covering food safety standards, quality systems, packaging safety, warehouse security, and product transportation. PHC is committed to fostering long-term partnerships by regularly reviewing key suppliers to assess industry trends and potential Environment, Social, and Governance and Economic (ESG) risks that may impact future business operations.

Additionally, PHC encourages suppliers to adhere to Yum! Brands Inc.’s supplier code of conduct, which outlines ESG best practices. In 2024, PHC communicated these guidelines to all new suppliers and continues to expand engagement across all supplier groups.

Performance in 2024

Total Number of Suppliers Supplier Categories Number of Suppliers Percentage New Suppliers 22 18 Critical Tier 1 Suppliers 11 9 Critical Non-Tier 1 Suppliers 101 85 Supplier Code of Conduct Acknowledgement Number of Suppliers Percentage Suppliers that signed the Supplier Code of Conduct 28 24 Payment Period for Suppliers Day Supplier Credit-Term according to Supplier Code of Conduct 30 Actual supplier average credit-term in 2024 45 Supplier Compliance Violations Case Number of violations 0 PM Thoresen Asia Holdings: PMTA

Value Chain Management Approach

PMTA adheres to sustainable growth and takes into account all groups of the stakeholders in the value chain. PMTA’s main subsidiary, Baconco, is one of the market leaders in Vietnam’s agrochemical industry. Baconco’s STORK trademark is widely recognized and renowned for its product quality. Baconco selects overseas suppliers that are well-known for their quality and credibility in order to import the raw materials with higher quality than local suppliers in Vietnam to use in its production process. Baconco also conducts domestic marketing campaigns by organizing small meetings, seminars and events which target different types of customers for different purposes. For example, Baconco organizes small meetings with farmers mainly to advise them on suitable fertilizers to use and to also provide Baconco’s products knowledge and introduce other products. The activities also allow Baconco to gain insights, informative feedback, and recommendations from the customers.

Unique Mining Services (UMS)

Value Chain Management Approach

UMS has procurement standards for coal procurement, selection and import that involves quality assurance by a team of experts and professionals. The inspection qualifications that the supplier must meet includes carbon content, humidity content, sulfur dioxide content, and quantity of reserve coal. If the qualifying examination results meet the standards, UMS will then purchase such coal. In addition, the company also specifies the standard for the domestic delivery processes to fully cover coals in an appropriate condition during transportation. In terms of international suppliers, a procurement process has been set out to select a reliable and standardized transportation provider. The service provider must import coal in compliance with legal and customary formalities. In 2024, however, the company did not import coal from international mines. Additionally, the company provides pre- and post-sales consultation and service to customers to deliver products at maximum quality.

Asia Infrastructure Management (Thailand): AIM

Value Chain Management Approach

With a strong commitment to long-term growth and sustainable development, the company has developed strict and equitable guidelines for selecting suppliers who meet the Waterworks Authority standard to maintain the quality of service. To encourage the core sustainable long-term value, the company always prioritizes selecting suppliers who share the same goal of being environmentally friendly. Therefore, the company is in the process of studying the potential of value chain management with all groups of suppliers to grow sustainably together.

-

Cybersecurity and Data Privacy

-

Cybersecurity andData Privacy

Technological resources are business assets that require efficient management, including preventive measures and the definition of data usage security levels. This management is crucial for maintaining the privacy of stakeholders' personal data and data used in the Group's business operations.

Cybersecurity and Data Privacy (3-3)

Rapid technological change and development, coupled with the increasing sophistication of cyber threats, present risks related to data privacy and cybersecurity. These risks include computer viruses, hacking, ransomware, unauthorized use or disclosure of user data, and the loss or leakage of sensitive Group data and stakeholders' personal data. Therefore, cybersecurity and the safeguarding of personal data are critical corporate risk factors of utmost importance to the Group. This prioritization aims to reduce potential risk levels and prevent negative impacts on the Group, both monetary and non-monetary, such as fines from legal actions, damages from ransomware or extortion, reputational damage, and loss of revenue or profit, or customer base due to diminished trust in the Group's reputation and image, etc. The Group is committed to investing in technology, enhancing work process efficiency, increasing cybersecurity awareness among personnel, and continuously promoting the appropriate use of digital technology.

Thoresen Thai Agencies: TTA

Cybersecurity and Data Privacy Management Approach

Information and Cyber Security Management Policy

The Company recognizes the inherent risks associated with information technology and, therefore, prioritizes the care and protection of its information technology resources. The Information and Cyber Security Management Policy serves as the operational framework that all users must adhere to, in compliance with the Computer Crime Act B.E. 2550 (2007). This Policy establishes the standard for protecting the organization and against inappropriate user actions. The Company collects personal data only when necessary for its operational purposes, depending on the individual's relationship or activity with the Company, and the type of product or service used. Individuals are notified of these practices before or at the time of personal data collection. Explicit consent is obtained from individuals before or at the time of collecting their personal data.

The current Policy, reviewed and updated in 2024 to ensure compliance with relevant laws and standards, is disclosed on the Company's website ( https://www.thoresen.com/en/corporate-governance/corporate-policy-documents)

Key elements of this policy encompass regulations for controlling and preventing information access to ensure appropriate use of information resources and effective management for personal data security. This framework enables the control of user operations, minimizing risks, and ensure adherence to relevant laws. Encryption is employed for data transmission over the internet, and access to personal data is controlled and restricted to authorized personnel for both document and electronic formats. The Company has established data backup guidelines aligned with Backup and Recovery Best Practice standards, defining scope, data storage media, backup frequency, and data replication to various locations. Recognizing the rapid evolution of information technology, the Company conducts annual reviews of related policies.

In addition, the Company focuses the auditing and assessment of cybersecurity and data privacy risks, including risk identification, assessment, and control to acceptable levels. Appropriate risk management and mitigation plans are in place. Details on risk assessments and risk management guidelines are available in the Risk Factors section of the 2024 Form 56-1 One Report.

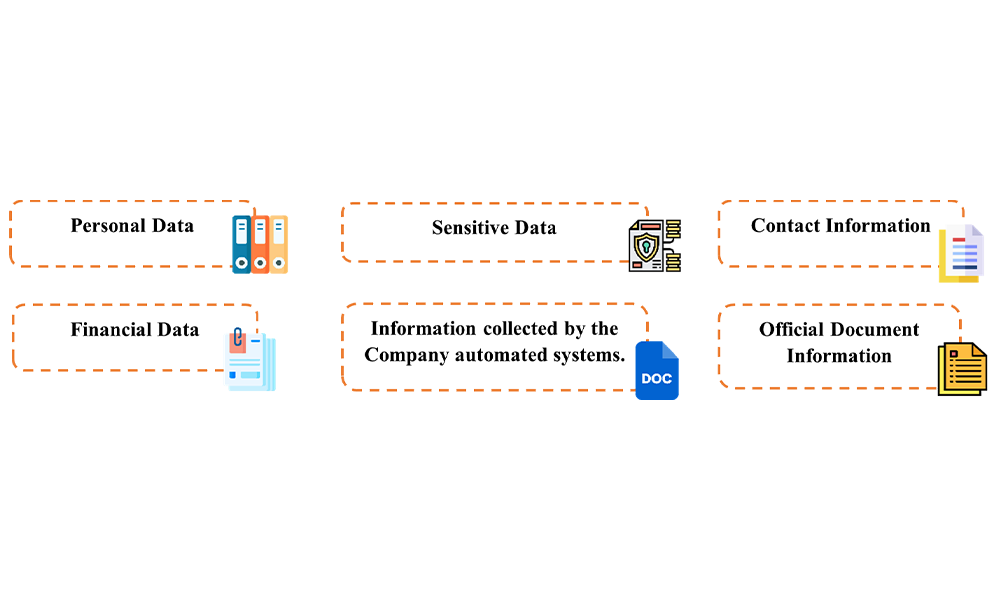

Privacy Policy

The Company maintains a Privacy Policy that adheres to the Personal Data Protection Act B.E. 2562 (2019), as well as other pertinent laws and regulations enforced in Thailand, to govern its data privacy operations. The core principles of this policy are to collect and store personal data lawfully, ethically, and only to the extent necessary for the Company's operational purposes. Data collection is limited in purpose, scope, and method. The data is categorized as follows:

Channels of Receiving Complaints

TTA provides channels for inquiries or requests for further information regarding personal data protection, collection, use, disclosure, and the exercise of data subject rights. These channels are also available for lodging complaints. Contact can be made through the following means:

Thoresen Thai Agencies Public Company Limited

26/26-27 Orakarn Building, 8th Floor, Soi Chidlom, Ploenchit Road,

Lumpinee, Pathumwan, Bangkok 10330Telephone: 02-250-0569 to 74

Data Protection Officer

26/26-27 Orakarn Building, 8th Floor, Soi Chidlom, Ploenchit Road,

Lumpinee, Pathumwan, Bangkok 10330เบอร์โทรศัพท์: 02-250-0569 to 74

Email: dpotta@thoresen.com

Role and Responsibilities of the Board of Directors regarding Information Technology

The Company designates the Board of Directors as responsible for overseeing information technology governance, innovation, and information technology risk management, in accordance with relevant standards and laws. The Board considers policies and procedures related to the management and mitigation of cyber and information technology risks, integrating these into enterprise-wide risk management. This integration spans from risk or business opportunity identification, assessment, and prioritization to the determination of management measures, monitoring and reporting, and the annual review of the information and cybersecurity management policy to ensure compliance with corporate governance principles. The Information Technology Department serves as the primary unit responsible for overseeing and managing the organization's cybersecurity. This includes actively monitoring and responding to threats and maintaining information technology systems to be secure and up to date.

Cybersecurity and Data Privacy Activities and Initiatives

Employee Training on Personal Data

In 2024, the Company provided "PDPA Awareness Training 2024" on 12 December 2024, to educate executives and employees about personal data protection. The online training, attended by 41 participants, generally covered types of personal data, an overview of the PDPA law, and relevant work processes. Experts from Ragnar Corporation Company Limited presented the training.

Preparation for ISO 27001 Certification

The Company is pursuing ISO 27001 certification to enhance the efficiency of its information technology security and to strengthen the protection for all groups of stakeholders. To this end, the Company has undertaken several preparatory measures, including:

- Updating the Information and Cyber Security Management Policy.

- Conducting a Cybersecurity Assessment to evaluate potential risks and vulnerabilities.

Communication on Personal Data Protection and Cybersecurity

The Company communicates information regarding personal data protection and cybersecurity to employees through pop-up notifications and the Company's internal portal system, ensuring employees can access this information at their convenience.

Phishing E-mail Attack Simulation

In 2023, the Company launched a Phishing E-mail Attack Simulation project to train employees to effectively handle and respond to phishing e-mail threats. This initiative is a key measure to mitigate the risk of phishing attacks. Furthermore, the project aims to build accurate knowledge and understanding of phishing tactics and to enhance employee vigilance in identifying suspicious emails.

Project Goal

No employees have fallen victim to this test within 2 years since the project's inception.

Implementation Period

Starting in 2023, and repeating the test, changing the attack method, until no employees fall victim.

In 2024, the Company conducted the attack simulation with 126 employees. The results showed that 116 employees passed the test, and 10 employees failed (fell victim), which translates to pass and fail rates of 92.06 percent and 7.94 percent, respectively. Importantly, all 10 employees who failed completed the follow-up Phishing E-mail course, representing a 100 percent completion rate for this group. of those who failed.

Compared to the previous year, the failure rate in the 2024 test decreased by 40 percent. Moving forward, the Company intends to conduct the Phishing E-mail attack simulation every two months, employing diverse email formats.

Performance in 2024(418-1)

Data Performance Cybersecurity and Data Privacy Training Participation (percentage) Board of Directors 100 Executives 100 Employee 71.43 Complaints and Incidents of Cyber Attacks and Data Leaks Complaints regarding customer privacy breaches and loss of customer data (case) 0 Complaints from external parties 0 Complaints from regulatory authorities 0 Number of cyber-attack cases (case) 0 Number of data leak cases (case) 0 Results of the Phishing E-mail Attack Testing Project (person) Total participant 126 Participants who passed the test 116 Participants who failed the test (fell victim) 10 Participants who failed the test but passed the Phishing Email course 10 Thoresen Shipping: TSS

Cybersecurity and Data Privacy Management Approach

Thoresen Shipping prioritizes cybersecurity management and personal data protection. Recognizing the crucial role of information technology systems in modern operations which helps boost the operation’s convenience, speed, efficiency, and overall effectiveness. Thoresen Shipping emphasizes the appropriate and secure use of information technology by both crews and office personnel, ensuring adherence to the Group's business policies, the Computer Crime Act, and other relevant regulations, ultimately maximizing benefits for all groups of stakeholders. The security and protection of personal data across all relevant functions is considered paramount to ensuring smooth, stable, and sustainable operations.

To ensure compliance with applicable laws and regulations, Thoresen Shipping adopts TTA’s Information and Cyber Security Management Policy and Privacy Policy as a management framework to proactively prevent and maintain the security of personal data. Furthermore, the company’s Information Technology department serves as the primary unit responsible for overseeing the company's information security, including system development. It also acts as the central point of contact for coordinating and collaborating with the company's various operating system service providers.

Channels of Receiving Complaints

The company provides channels for inquiries, questions, and complaints related to personal data protection, collection, use, or disclosure of personal data through the following channels:

Thoresen Shipping Singapore Pte. Ltd

Contact Address: 127A TELOK AYER STREET, Singapore (068596)

Telephone: +65 6578-7000

Data Protection Officer

Contact Address: 127A TELOK AYER STREET, Singapore (068596)

Telephone: +65 6578-7000

Email: dposhipping@thoresen.com

Cybersecurity and Data Privacy Activities and Initiatives

Review of Cybersecurity Awareness

In 2024, TSS reviewed cybersecurity awareness in relation to the Corporate Governance Policy and Code of Business Conduct. This review encompassed guidelines on information technology system usage and cybersecurity measures. Communication of these guidelines was disseminated to office staff via online channels, e-mail, and the Blink Application. This multi-channel approach ensured that officers and employees across all departments understood and recognized the importance of cybersecurity, promoting efficient and secure operations. To further assess understanding, the Corporate Communications Department of Thoresen Shipping distributed cybersecurity and data privacy regulations for employee to acknowledge. As a result, it was determined that 71.43 percent of employees had received cybersecurity communications.

Performance in 2024(418-1)

Data 2024 Results Cybersecurity and Data Privacy Training Participation (percentage) Executives 100 Employee 71.43 Complaints and Incidents of Cyber Attacks and Data Leaks Complaints regarding customer privacy breaches and loss of customer data (case) 0 Case Complaints from external parties 0 Complaints from regulatory authorities 0 Number of cyber-attack cases (case) 0 ครั้ง Number of data leak cases (case) 0 ครั้ง PH Capital: PHC

Cybersecurity and Data Privacy Management Approach

PHC prioritizes cybersecurity and the privacy rights of customers, and strictly complies with relevant laws and human rights principles. To this end, the company has an Information Security Management System Manual to serve as a framework for its information security operations. PHC also thoroughly communicates various security policies and measures to internal and external stakeholders to strictly protect the personal data of customers and all groups of stakeholders.

Channels of Receiving Complaints

- Call Center : 1150

- Website : www.pizzahut.co.th

- Mobile Application : Pizza Hut Thailand

The company has assigned the Head of the IT Department as the primary person responsible for overseeing the information security system. This responsibility covers all aspects from risk assessment and the development of appropriate security measures, to driving effective implementation throughout the organization. Furthermore, the company maintains a Contingency Plan to manage business continuity and prevent potential impacts from information system failures or severe damage, ensuring the ability to recover the system within an appropriate timeframe. Should customers encounter issues, they can file complaints through any of Pizza Hut's channels.

Data Security

PHC maintains the security of its information systems utilizing the AWS Cloud system, an internationally recognized standard, coupled with a Web Application Firewall (WAF Security) system to prevent cyberattacks. This approach effectively protects the Company's diverse data assets, including customers' personal data.

Performance in 2024(418-1)

Indicator 2024 Results Complaints and Incidents of Cyber Attacks and Data Leaks Complaints regarding customer privacy breaches and loss of customer data (case) Complaints from external parties 0 Complaints from regulatory authorities 0 Number of cyber-attack cases (case) 0 Number of data leak cases (case) 0 Mermaid Maritime: MML

ISO 27001:2022 Information Security Management System Certification

MML has been certified to ISO 27001:2022 Information Security Management System since 1 April 2024 to demonstrate its commitment to information security management, protecting and preventing potential threats and damages, and reducing the risk of data breaches and building confidence among stakeholders with a reliable standard system.

-

Research and Innovation Development

-

Research andInnovation Development

The Group strives to innovate and utilize innovations to develop business processes and new products and services, creating added value and responding to evolving global trends.

Research and Innovation Development (3-3)

Innovation and technology are essential drivers for sustained business growth. In today's rapidly evolving global landscape, consumer expectations for goods and services are constantly changing. The Group recognizes the importance of innovation and technology and therefore prioritizes fostering innovation and creating new solutions across all business units. This proactive approach enables the Group to effectively address emerging challenges, adapt to the dynamic technological and innovative environment, and simultaneously identify and capitalize on new business opportunities.

Guided by the Company's core values, which emphasize the pursuit of excellence through novel ideas and development approaches, the Group actively promotes creative initiatives that generate business value in response to evolving market conditions. The Group prioritizes cultivating a work environment that stimulates innovation and creative thinking, encouraging employees to enhance work processes, products and services to achieve maximum efficiency. To ensure strategic alignment, the Group develops research and innovation development strategies that are consistent with the Group's overarching business development plan. This alignment ensures that innovations are effectively tailored to meet the diverse needs of each business group's specific customer base. The Group emphasizes both process and product innovation, empowering business units not only to meet customer demands but also to optimize internal workflows for greater efficiency. Ultimately, these comprehensive efforts enhance the organization's competitiveness, bolster customer appeal, and strengthen investor confidence in the Group's commitment to continuous improvement across all dimensions.

Creativity Promotion and Innovation Management Policy

The Group supports and promotes the cultivation of creativity throughout the organization, actively driving innovation through the establishment of a formal policy of Creativity Promotion and Innovation Management Policy. This policy is strategically focused on generating innovations that deliver tangible business value while also creating positive value for all groups of stakeholder, incorporating social and environmental awareness. The Group prioritizes establishing an organizational culture that fosters the generation of new ideas and innovations, encompassing product innovation, production processes, work processes, services, and the creation of new businesses. The Group firmly believes that a consistent emphasis on developing diverse types of innovation is crucial for effective adaptation to dynamic changes. This approach enables the Group to comprehensively meet the needs of all groups of stakeholders, thereby enhancing competitive advantage and building robust trust with all groups of stakeholders, which in turn facilitates steady and sustainable organizational growth. This Policy was announced on 2 September 2024 and its scope encompasses TTA and all subsidiaries, as detailed below:

Practices

- Align vision, strategies, and policies regarding creativity promotion and innovation management with the Company’s vision, mission, and strategy.

- Entrust all executives and employees with supporting, driving, and complying with Creativity Promotion and Innovation Management Policy to continuously maximize work efficiency and business competitiveness.

- Strive to develop innovation management system for the Group, society, and environment under a clear innovation management framework. A corporate-level responsibility structure as well as specific roles, duties, and work processes are defined to ensure that vision, strategy, and Creativity Promotion and Innovation Management Policy will be achieved as intended.

- Provide appropriate budget support and other resources for innovation management, both short- and long-term.

- Develop a systematic method and mindset in collecting and evaluating innovative ideas. Stimulate creativity in ways that consistently generate fresh ideas.

- Provide a systematic innovation process, namely 1) ideation 2) business feasibility assessment 3) transformation of ideas into a project 4) product, service, and process testing 5) preparation of new commercial operation, production process, and work process for implementation 6) implementation of a new product, service, production process, and work process.

- Conduct assessment of work process effectiveness as well as constant follow-up and performance report to relevant executives to ensure innovations, products, services, and processes that add to business value while creating value for stakeholders.

Fostering an Atmosphere for an Innovation-Driven Organization

- Create an environment where innovation and collaboration flourish. Motivate and encourage creative idea contributions from employees.

- Accept risks reasonably. Be open to failure.

- Encourage teamwork and collaborate with external parties.

- Educate and promote learning. Empower employees through inventions, observational field studies, exhibitions, and showcase of works of creativity and innovation.

- Offer proper recognition for innovations or innovation teams and innovative works that create value to the Group and related parties.

- Promote scaling of successful innovations to inspire and foster a learning culture across the Group.

- Invest in upskilling initiative to spark creativity, drive continuous development through innovation implementation, and build an innovation-friendly atmosphere and motivation to innovate.

Thoresen Thai Agencies: TTA

Research and Innovation Development Management Approach

TTA has established Creativity Promotion and Innovation Management Policy to serving as a framework for innovation initiatives across the Group. This policy focuses on fostering creativity within the organization, which will drive the development and improvement of products, services, and work processes, ensuring efficient alignment with the operational guidelines of each company.

Thoresen Shipping: TSS

Research and Innovation Development Management Approach

โThoresen Shipping is committed to operating as a sustainable organization, with the goal of minimizing the environmental impact of its operations. TSS aims for maximum operational efficiency within its fleet while reducing its environmental footprint, adhering to the Group's vision, policies, and established practices. The Technical Management Department is responsible for overseeing research and development of innovations to enhance the quality of the company's fleet services. This department collaborates with various relevant departments across the organization to optimize operational efficiency.

Research and Innovation Development Activities and Initiatives

Installation of Ship Speed-Enhancing Equipment

The company has implemented the installation of ship speed-enhancing equipment on propeller shafts to improve hull efficiency. This enhancement allows vessels to achieve higher speeds while maintaining the same engine speed, resulting in fuel savings during navigation. The installed equipment includes devices such as Mewis ducts, Swirl fins, MT Fast, Rudder bulbs with fins, PSV, PSS, and HEP. These devices improve water flow and ship propulsion efficiency, leading to enhanced performance. They also contribute to maintaining propeller condition, extending its lifespan. Furthermore, by reducing fuel consumption, they also contribute to lowering greenhouse gas emissions from the ship's engine.

PH Capital: PHC

Research and Innovation Development Activities and Initiatives

Lead 6th by CPN Project

PHC participated in the "Lead 6th by CPN" program, organized by CPN. The program's objective was to provide knowledge to participating SMEs, focusing on training and developing employees in product development and fostering collaboration between SMEs and Pizza Hut. The emphasis was on leveraging combined strengths to create appealing new products (New Product Development) designed to attract new customer segments. This activity offered expertise in various areas, including business acumen, marketing, finance, and fundamental pizza-making knowledge. As a result, 39 SMEs gained valuable knowledge. The program also incorporated group work focused on developing new product concepts, evaluating 3 promising concepts for further study and feasibility assessment for potential launch in Pizza Hut restaurants.

Raw Material Innovation Improvement: Frozen Dough

PHC has advanced raw material innovation by adopting Frozen Dough from Yum! Brands Inc., the originator of this innovative product. Frozen Dough, an Italian-style dough, promotes product consistency, reduces dough preparation time within restaurant locations, and minimizes food waste in scenarios of lower-than-expected product sales.

Performance in 2024

Quantitative Benefits from Innovation Development Baht Cost of investment for Innovation Development 436,783 Siam Taco: STC

Research and Innovation Development Activities and Initiatives Container Upcycling Project

Container Upcycling Project

Taco Bell celebrates its new branch with a container model for the first time at Bangchak Gas Station, Ramintra Km. 6.5 branch. The Taco Bell store at Bangchak Gas Station, Ramintra Km. 6.5, newly opened with the innovation of upcycling used containers that have been appropriately selected for quality, used as the main component of the first Taco Bell branch, is first-of-its-kind concept for Taco Bell enhances sustainability, offering cost efficiency and faster construction timelines. Using containers results in less waste and debris than traditional construction, and when it is necessary to relocate the store, it can be done conveniently and quickly, reducing the amount of waste and debris from the store relocation process. The container model also enables STC to establish stores in limited-space areas, creating employment opportunities in the Ramintra community and contributing to local economic growth.

-

Enterprise Risk and Crisis Management

-

Enterprise Riskand Crisis Management

Effective and appropriate risk and crisis management are key drivers for building business continuity by enabling timely preparation for and response to uncertain events.

Enterprise Risk and Crisis Management (2-12, 3-3)

Risk management and crisis management are essential for business operations in today's uncertain world, characterized by external and internal factors such as natural disasters, economic shifts, evolving regulations, cyber threats, and various sustainability risks. The Group is committed to effective risk management that enables timely preparation for and rapid response to crises. This proactive approach aims to minimize potential losses and negative impacts, facilitate adaptation to business changes, ensure operational continuity, and ultimately achieve business objectives and strategic goals while fostering value and trust among all groups of stakeholders.

TTA Group Enterprise Risk Management Policy